Custom Solutions

Injection Molding

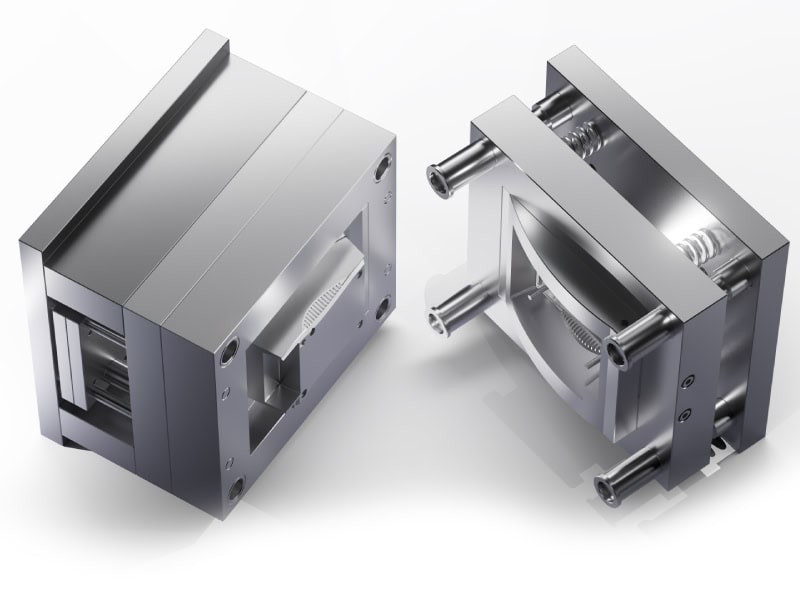

We specialize in the design, engineering, and fabrication of precision molds used in the plastic injection molding industry. Our specialty includes the manufacturing of molds used to produce precision aerospace, medical, and automotive components, but our experience and expertise extends to a wide range of industries. The first step to creating a premium quality mold is creating a CAD model and simulating the molding process. Designs can be created based on a technical drawing of the molded component or a physical specimen that must be reverse engineered. If needed, we can also provide guidance on optimizing a specific component for the injection molded process. There may be ways to slightly modify the part which can save costs without reducing the functionality of the component. Taking this into account early on in the mold design process can greatly reduce production costs. Depending on the component design, specialty features such as hydraulic core pull, two-shot, unscrewing, and hot runner mold types can be used to accommodate unique part geometries.

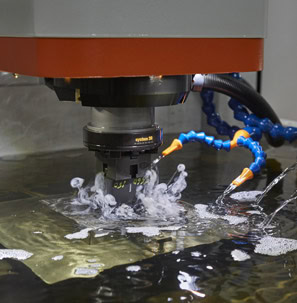

Once the design has been finalized and approved, the precision mold is machined using advanced CNC milling and EDM equipment. CNC mills have 5-axis machining capabilities, allowing even the most complex designs to be milled in a single set-up. This not only increases machining efficiency, which in turn reduces overall costs and lead time, but increases the precision of the tolerances that can be held since cuts are referenced off a single point, eliminating the variability that inherently results from multiple set ups. Electrical discharge machining, or EDM, equipment provides the ability to machine components to within ±0.0001" and with surface finishes fine enough to meet the quality specifications of the most demanding manufacturing industries.

We are ISO 9001:2008 certified and perform all quality checks and inspections according to our stringent quality management system. CMM equipment is present on the shop floor to perform dimensional inspections when needed.

| Plastic Injection Molds Capabilities |

| CAD Modeling |

| Design |

| Engineering |

| Reverse Engineering |

| Inspection |

| Mold Flow Analysis |

| Machining |

| Fabrication |

| Testing |

| Tool History Documentation |

| Technical Support |

| Injection Mold Types |

| Hydraulic Core Pull |

| Hot Runner |

| Two-Shot |

| Unscrewing |

| Material Applications |

| Polypropylene |

| Nylon |

| ABS |

| Polycarbonate |

| Acetal |

| PEEK |

| Polystyrene |

| PFA |

| Mold Sizes |

| For Presses up to 750 Tons |

| Additional Services |

| CNC Machining |

| Electrical Discharge Machining |

| Plating |

| Heat Treating |

| Dimension Inspection |

| Testing |

CNC / High Speed Machining

Our CNC machining services are backed by a 30 year history of providing the most demanding industries with precision machined molds and production components. We use the most advanced milling equipment available to produce a wide range of steel, stainless steel, aluminum, and titanium parts for the aerospace, medical, and automotive industries. Our 5-axis CNC milling centers are equipped with hard milling and high speed machining capabilities which allow us to hold precision tolerances while machining high strength material and complex geometries with maximum efficiency.

Without 5-axis machining, complex aerospace and medical components would have to undergo multiple machining cycles, resulting in additional set-ups and longer lead times. The elimination of additional set-ups not only reduces overall lead time, it increases the precision we are able to achieve by reducing registration errors that can result from multiple set-ups. Additionally, since in CNC machining there is no need to produce dedicated hard tooling, these processes can be used to economically produce lower volumes of custom parts.

Our quality management system is backed by an ISO 9001:2008 certification, which represents the highest standard for quality in the industry. Dimensional inspections are performed using CMM equipment to verify conformance to all applicable quality specifications.

Electrical Discharge Machining (EDM)

We provide precision machining services through the use of sinker and wire electrical discharge machining, or EDM, equipment. In electrical discharge machining, a concentrated electrical current is used to remove minute portions of the substrate material in accordance with the programmed design. In the sinker EDM process, a custom machined electrode is used to remove material in the shape of the electrode. The electrode is plunged into the material and erodes the material surface from the top down. The electrical power is fine tuned to balance speed and surface finish with higher power settings used to create quick rough cuts and low power settings used to produce a very fine surface finish. In the wire EDM process, a thin wire is used to erode the surface of the part to create straight or tapered cuts in the desired pattern. Different diameters of wire can be used depending on the precision and complexity of the cut.

Any conductive material can be machined using EDM processes, but electrical discharge machining is especially well suited to the machining of high strength alloys. High strength steel alloys such as Inconel and Monel are challenging to machine using traditional milling processes, as they rapidly work harden, causing machining to be laborious and costly. If materials are tempered prior to machining and heat treated after the fact, precision is often lost in the distortion that can result from the heat treating process. In electrical discharge machining, the properties of the material being machined are not affected, meaning tolerances as tight as ±0.0001" can be held and no tempering of the material is required.

Modern EDM equipment is capable of cutting at much higher speeds than older systems, which allows us to provide EDM produced parts in a wider range of volumes than in decades past.

- General Capabilities

- Sinker Electrical Discharge Machining

Wire Electrical Discharge Machining

Small Hole Drilling EDM

- Equipment Capabilities

- 4-Axis

CNC Capabilities